Technology transfer is one of the most complex yet essential steps in the biopharmaceutical lifecycle, ensuring that a drug candidate developed in one setting is reproduced reliably at the clinical and commercial scales. As pipelines diversify to include modalities such as ADCs, mRNA therapeutics, and multispecific antibodies, the significance of transfer processes has become even greater.

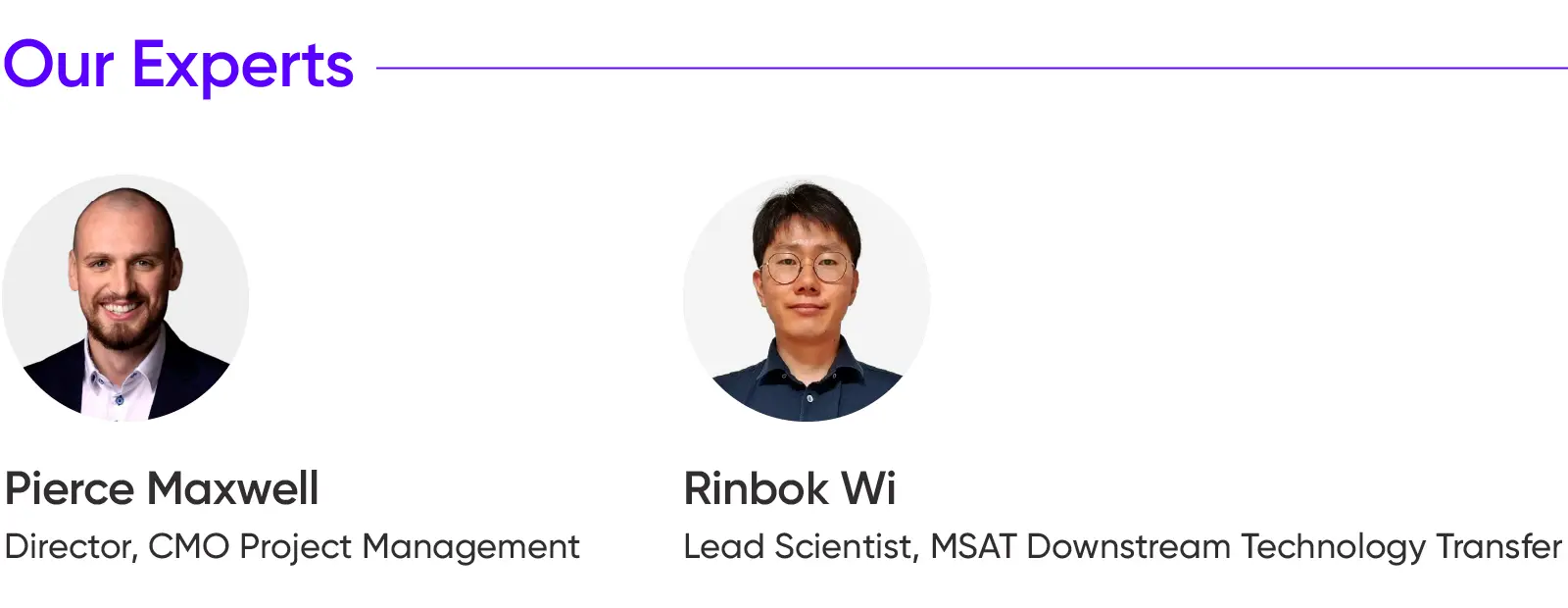

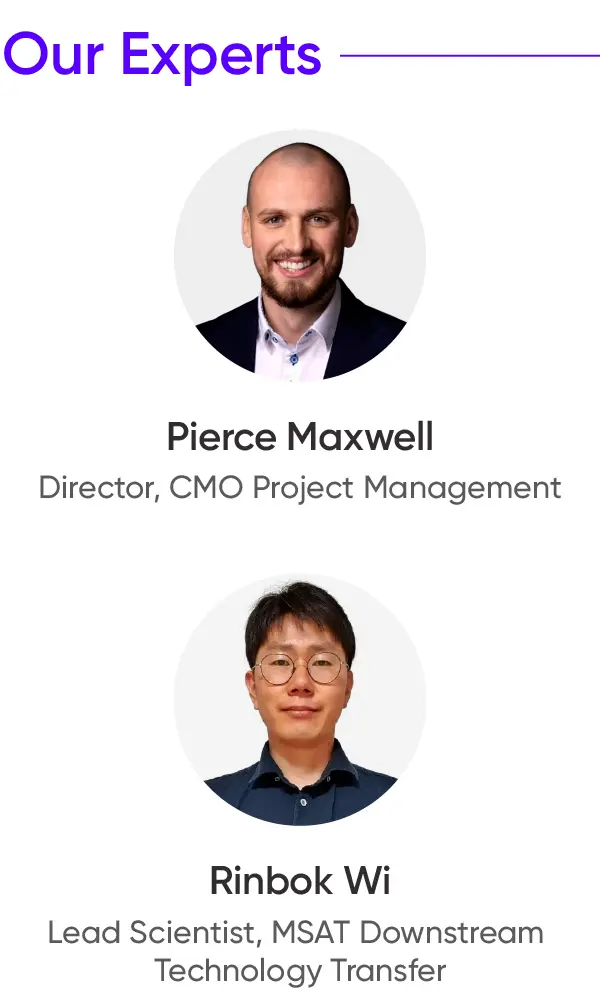

In this edition of Ask Our Experts, leaders from the Samsung Biologics MSAT and Project Management teams share how structured methodologies, harmonized platforms, and digital innovations enable seamless, risk-managed, and efficient transfers for global partners.

Q1. What digital strategies are applied to accelerate transfer and strengthen collaboration?

Digitalization has transformed how technology transfer is managed and communicated. Our client portal provides a secure, real-time environment where clients can monitor progress, access key documents, and exchange data seamlessly. This system reduces delays caused by manual communication and supports a more transparent, collaborative workflow.

Additionally, we leverage internal knowledge tools, such as the Bioprocess Library, a centralized data storage built from our cumulative experience across diverse projects. Using this platform, teams can identify potential challenges and streamline document reviews. Along with these digital tools, our advanced technologies help accelerate decision-making and ensure each transfer is executed with both speed and precision.

Q2. How do you manage data confidentiality and ensure secure transfer between companies?

Data security is foundational to every collaboration. Client information is shared through secure platforms, such as the client portal, where each client has an individual login through which to access their project information. This platform ensures confidentiality while allowing stakeholders to access the information they need without the risk of compromise.

In addition to technical safeguards, we maintain strict internal governance—from access control to audit trails—to uphold data integrity throughout the project lifecycle. This combination of system security and procedural discipline gives partners the confidence that sensitive data remains fully protected.

Q3. What capabilities do you currently offer for ADC programs?

We offer conjugation services, and are building drug product and lyophilization capabilities to support large-batch production across multiple vial sizes. These offerings are grounded in our standardized processes and equipment, providing flexibility and consistency for each ADC program.

Looking ahead, we are expanding toward end-to-end ADC services that will include linker-payload supply. This integrated approach will allow clients to advance their ADCs through a single, streamlined supply chain—from conjugation to final drug product—reducing operational complexity and ensuring continuity across production stages.

Q4. How often do you come across a process that requires significant development to ensure successful transfer?

The answer to this question largely depends on the product’s development phase. For example, a clinical product that is scaling up to a larger process for the first time tends to require more optimization, while approved commercial programs with established manufacturing histories usually transfer smoothly.

When additional development is needed, our teams focus on identifying and addressing potential challenges early—through data review, risk assessments, and small-scale verification studies. These activities allow us to refine parameters, confirm process robustness, and maintain overall timelines. The goal is not only to execute a transfer successfully but also to strengthen the process in preparation for future lifecycle stages.

Q5. How do you keep technology transfer projects consistent when they’re carried out across different facilities?

Consistency begins with a unified approach to project management. Our teams operate with standardized, systematic models that clearly define responsibilities, timelines, and communication channels from the outset, ensuring that every function remains aligned throughout the transfer. This structured coordination allows projects to progress efficiently, even when multiple facilities are involved. Each site follows the same design principles, equipment standards, and documentation systems, minimizing the need for requalification and enabling smoother, faster execution.

Building on this foundation, we recently introduced the ExellenS™ framework, which is applied consistently across all sites. By emphasizing standardization, simplification, and scalability, ExellenS™ further enhances consistency across facilities and enables technology transfers to be completed with greater speed, reliability, and transparency across our global network.

Q1. How do you ensure consistency and reliability in your transfer process?

We follow a standardized operating procedure (SOP) that guides each stage of the transfer—from assessing new product introductions and transferring analytical methods to preparing production systems, GMP documentation, and lifecycle validation.

The SOP also provides templates that clearly define responsibilities and summarize activities. This structure creates transparency across teams, reduces variability, and strengthens reproducibility—all of which are essential for dependable execution and regulatory compliance.

Q2. Do you source materials from multiple sites during process performance qualification (PPQ) runs?

The PPQ demonstrates that a process can run reliably under real manufacturing conditions. To build confidence, we account for variability where it matters, such as in raw materials, manufacturing trains, and equipment, so that the results are statistically meaningful.

For single-use materials, we generally do not source all alternatives from multiple sites when performing PPQ runs. The decisions are based on structured risk assessments. In many cases, suppliers provide comparability data for customized components, which helps in validating equivalency and minimizing risks to product quality without the need to evaluate all types of alternative materials from multiple sites.

Q3. How are analytical methods and reagents handled during technology transfer?

Analytical method transfer is a critical part of the process. The sending unit provides training, test procedures, validation records, and critical reagents, along with reference standards. The receiving unit then carries out a gap assessment to confirm readiness. This assessment covers (1) test method availability, (2) the laboratory (equipment, reagents, consumables), and (3) sample management, such as storage capacity. By addressing these areas up front, we reduce the risk of delays and ensure that analytical methods are ready to support manufacturing.

Q4. When should a small-scale model be introduced?

A qualified scale-down model (SDM) should ideally be established before GMP manufacturing. Running small-scale verification batches helps confirm process performance and identify any refinements needed before moving to full-scale production. SDMs also play a critical role in process characterization and validation studies, including virus clearance, to confirm that small-scale study results accurately reflect full-scale production. Introducing them early increases confidence and reduces risks during large-scale operations.

Q5. What are the typical timelines for technology transfer, and what factors influence them?

Transfer timelines depend on the product stage, technical complexity, and scale. Clinical products in early stages often require more adjustments than established commercial products. At Samsung Biologics, with our harmonized facility design, standardized equipment platforms, and cumulative know-how, we have demonstrated successful transfers in as little as three months. This timeline was achieved without compromising regulatory compliance or quality.

With standardized processes, optimized facilities, and advanced digital tools, Samsung Biologics continues to strengthen technology transfer practices that reduce risk, accelerate timelines, and support the reliable scale-up of complex biologics.

To learn more about how we are leveraging an integrated, client-focused approach to accelerate technology transfers, contact us or visit our website: https://samsungbiologics.com/services/biopharma-manufacturing

Technology transfer is one of the most complex yet essential steps in the biopharmaceutical lifecycle, ensuring that a drug candidate developed in one setting is reproduced reliably at the clinical and commercial scales. As pipelines diversify to include modalities such as ADCs, mRNA therapeutics, and multispecific antibodies, the significance of transfer processes has become even greater.

In this edition of Ask Our Experts, leaders from the Samsung Biologics MSAT and Project Management teams share how structured methodologies, harmonized platforms, and digital innovations enable seamless, risk-managed, and efficient transfers for global partners.

Q1. What digital strategies are applied to accelerate transfer and strengthen collaboration?

Digitalization has transformed how technology transfer is managed and communicated. Our client portal provides a secure, real-time environment where clients can monitor progress, access key documents, and exchange data seamlessly. This system reduces delays caused by manual communication and supports a more transparent, collaborative workflow.

Additionally, we leverage internal knowledge tools, such as the Bioprocess Library, a centralized data storage built from our cumulative experience across diverse projects. Using this platform, teams can identify potential challenges and streamline document reviews. Along with these digital tools, our advanced technologies help accelerate decision-making and ensure each transfer is executed with both speed and precision.

Q2. How do you manage data confidentiality and ensure secure transfer between companies?

Data security is foundational to every collaboration. Client information is shared through secure platforms, such as the client portal, where each client has an individual login through which to access their project information. This platform ensures confidentiality while allowing stakeholders to access the information they need without the risk of compromise.

In addition to technical safeguards, we maintain strict internal governance—from access control to audit trails—to uphold data integrity throughout the project lifecycle. This combination of system security and procedural discipline gives partners the confidence that sensitive data remains fully protected.

Q3. What capabilities do you currently offer for ADC programs?

We offer conjugation services, and are building drug product and lyophilization capabilities to support large-batch production across multiple vial sizes. These offerings are grounded in our standardized processes and equipment, providing flexibility and consistency for each ADC program.

Looking ahead, we are expanding toward end-to-end ADC services that will include linker-payload supply. This integrated approach will allow clients to advance their ADCs through a single, streamlined supply chain—from conjugation to final drug product—reducing operational complexity and ensuring continuity across production stages.

Q4. How often do you come across a process that requires significant development to ensure successful transfer?

The answer to this question largely depends on the product’s development phase. For example, a clinical product that is scaling up to a larger process for the first time tends to require more optimization, while approved commercial programs with established manufacturing histories usually transfer smoothly.

When additional development is needed, our teams focus on identifying and addressing potential challenges early—through data review, risk assessments, and small-scale verification studies. These activities allow us to refine parameters, confirm process robustness, and maintain overall timelines. The goal is not only to execute a transfer successfully but also to strengthen the process in preparation for future lifecycle stages.

Q5. How do you keep technology transfer projects consistent when they’re carried out across different facilities?

Consistency begins with a unified approach to project management. Our teams operate with standardized, systematic models that clearly define responsibilities, timelines, and communication channels from the outset, ensuring that every function remains aligned throughout the transfer. This structured coordination allows projects to progress efficiently, even when multiple facilities are involved. Each site follows the same design principles, equipment standards, and documentation systems, minimizing the need for requalification and enabling smoother, faster execution.

Building on this foundation, we recently introduced the ExellenS™ framework, which is applied consistently across all sites. By emphasizing standardization, simplification, and scalability, ExellenS™ further enhances consistency across facilities and enables technology transfers to be completed with greater speed, reliability, and transparency across our global network.

Q1. How do you ensure consistency and reliability in your transfer process?

We follow a standardized operating procedure (SOP) that guides each stage of the transfer—from assessing new product introductions and transferring analytical methods to preparing production systems, GMP documentation, and lifecycle validation.

The SOP also provides templates that clearly define responsibilities and summarize activities. This structure creates transparency across teams, reduces variability, and strengthens reproducibility—all of which are essential for dependable execution and regulatory compliance.

Q2. Do you source materials from multiple sites during process performance qualification (PPQ) runs?

The PPQ demonstrates that a process can run reliably under real manufacturing conditions. To build confidence, we account for variability where it matters, such as in raw materials, manufacturing trains, and equipment, so that the results are statistically meaningful.

For single-use materials, we generally do not source all alternatives from multiple sites when performing PPQ runs. The decisions are based on structured risk assessments. In many cases, suppliers provide comparability data for customized components, which helps in validating equivalency and minimizing risks to product quality without the need to evaluate all types of alternative materials from multiple sites.

Q3. How are analytical methods and reagents handled during technology transfer?

Analytical method transfer is a critical part of the process. The sending unit provides training, test procedures, validation records, and critical reagents, along with reference standards. The receiving unit then carries out a gap assessment to confirm readiness. This assessment covers (1) test method availability, (2) the laboratory (equipment, reagents, consumables), and (3) sample management, such as storage capacity. By addressing these areas up front, we reduce the risk of delays and ensure that analytical methods are ready to support manufacturing.

Q4. When should a small-scale model be introduced?

A qualified scale-down model (SDM) should ideally be established before GMP manufacturing. Running small-scale verification batches helps confirm process performance and identify any refinements needed before moving to full-scale production. SDMs also play a critical role in process characterization and validation studies, including virus clearance, to confirm that small-scale study results accurately reflect full-scale production. Introducing them early increases confidence and reduces risks during large-scale operations.

Q5. What are the typical timelines for technology transfer, and what factors influence them?

Transfer timelines depend on the product stage, technical complexity, and scale. Clinical products in early stages often require more adjustments than established commercial products. At Samsung Biologics, with our harmonized facility design, standardized equipment platforms, and cumulative know-how, we have demonstrated successful transfers in as little as three months. This timeline was achieved without compromising regulatory compliance or quality.

With standardized processes, optimized facilities, and advanced digital tools, Samsung Biologics continues to strengthen technology transfer practices that reduce risk, accelerate timelines, and support the reliable scale-up of complex biologics.

To learn more about how we are leveraging an integrated, client-focused approach to accelerate technology transfers, contact us or visit our website: https://samsungbiologics.com/services/biopharma-manufacturing

Share article

Related Content