Drug Product Manufacturing for Biologics

Our CGMP manufacturing infrastructure is purpose-built to scale with your pipeline, and integrates seamlessly with process development and drug substance manufacturing

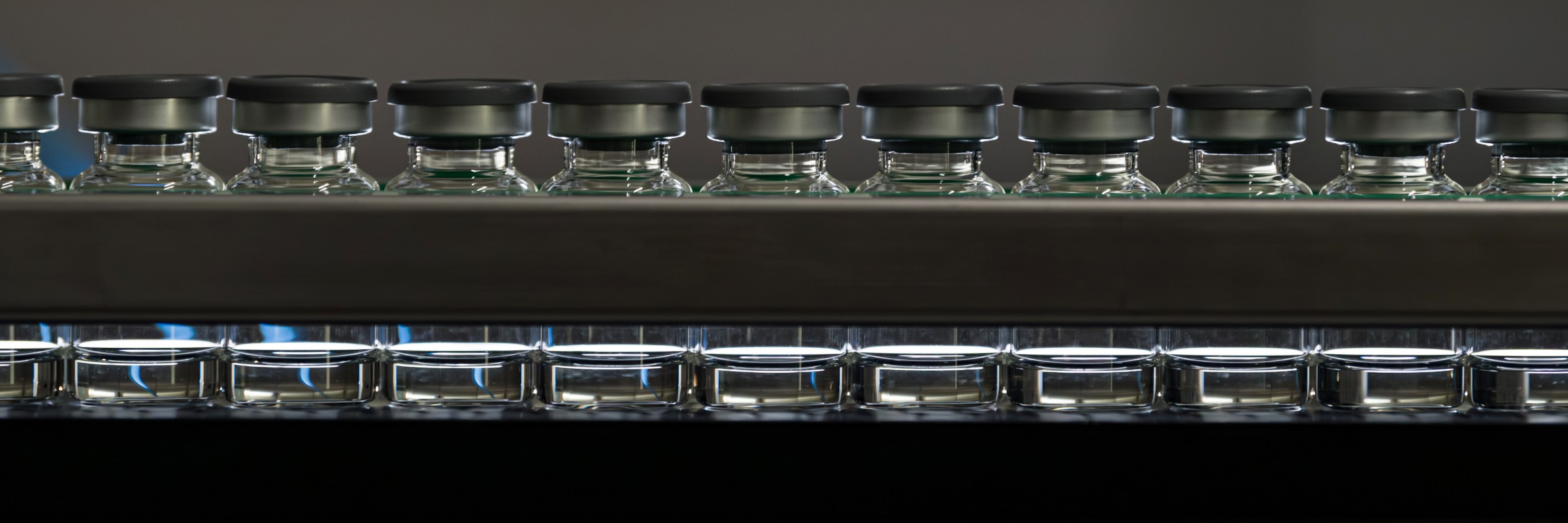

Flexible Aseptic Fill-Finish Capabilities

Our integrated approach to drug product manufacturing enables clients to transition smoothly from late discovery through cell line development, supporting on-time, compliant delivery to global markets.

-

-

Aseptic Filling Services

-

We provide clinical and commercial-scale aseptic filling for vials and prefilled syringes, covering both biologics and small molecule products.

Our automated lines support rapid changeovers with strict adherence to CGMP practices.

-

-

-

Lyophilization (Freeze-Drying)

-

Our lyophilization services offer scalable freeze-drying capacity for biologics and sterile injectables.

Fully integrated within our CGMP drug product suites, this capability helps maintain product stability and extend shelf life.

-

-

-

Finishing and Inspection

- We offer automated visual inspection systems and bulk secondary packaging to support batch release and product integrity. Quality assured through every stage of biopharma manufacturing.

-

-

-

Cold Chain Storage & Shipping

- We offer full cold chain logistics, with walk-in storage and freezer capabilities from 2-8℃ down to -70℃. Passive and active shipping methods ensure product integrity during global distribution. Our facility supports deep freezer storage and offers scalable analytical testing to validate stability.

-

-

-

Global Regulatory Support

-

Our services are approved in 20+ markets, with support for Type V DMFs and full CMC documentation.

Clients benefit from integrated regulatory affairs and quality assurance teams to support compliant market entry worldwide.

-

Your Trusted Fill-Finish Partner

-

Experienced MSAT & Tech Transfer

- Our MSAT experts lead process characterization, scale-up, and regulatory documentation for drug product projects, ensuring fast, smooth transitions to clinical or commercial supply.

-

Scalable Filling Solutions

- Our fill-finish lines support large batch sizes and a wide range of container types, tailored to your product needs. We handle both clinical fill-finish and global commercial supply.

-

Temperature-Controlled

- We offer a full spectrum of storage options from ambient conditions to deep cold (-70℃), supporting stability for temperature-sensitive products including mRNA therapeutics.

Related Content