End-to-End

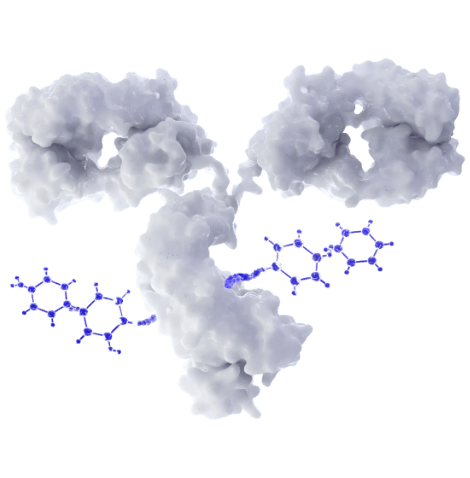

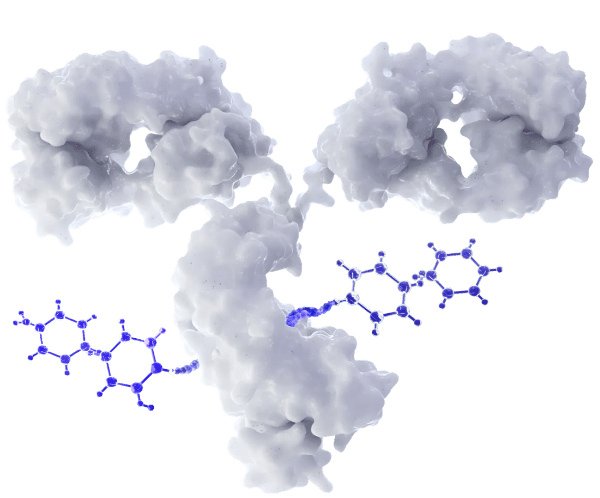

Antibody-Drug Conjugate (ADC)

Development & Manufacturing

its range of services to include bioconjugation and the end-to-end

development and manufacturing of antibody-drug conjugates (ADCs).

Our standalone ADC bioconjugation facility is supported by the same robust GMP

systems that power our high-capacity clinical and commercial biological manufacturing,

ensuring the highest standards of quality, compliance, and efficiency.

-

-

Dedicated ADC Facility for Streamlined Drug Substance Manufacturing

Our purpose-built ADC manufacturing site enables unified coordination from conjugation development to final formulation. This site features:

- Expedited drug substance (DS) delivery with flexibility at a single site

- Expertise in quality and proven operational track record

- Integrated systems with established tools and procedures

- Stable supply chain management system

Key Features of Our ADC Facility

-

Our ADC facility is equipped with single-use and stainless steel

reactors supporting up to a 500 L conjugation train, enabling

scalable and flexible ADC manufacturing. It includes full-scope

laboratories for ADC development, quality control (QC), and MSAT.

The facility is built to handle high-potency APIs (HPAPIs) with

stringent high-containment systems, achieving an Occupational

Exposure Limit (OEL) target of 5 ng/m³ to ensure safety and

compliance at every step.

Dependable ADC Services From a Trusted CDMO

We deliver end-to-end ADC services, from antibody production and conjugation development to full-scale ADC manufacturing.

As a leading ADC CDMO, Samsung Biologics ensures every stage of the antibody-drug conjugate lifecycle is supported with expert execution and regulatory precision.

Agile ADC Development Services

Our agile approach to ADC development is designed for speed, flexibility, and precision. With dedicated teams and streamlined workflows, we accelerate timelines from cell line development to ADC formulation, delivering robust solutions in as little as 12 months.

-

Late discovery

Tool box options for the best development choice

-

Conjugation

Method, parameter optimization, DAR variation control

-

Analysis

ADC Method development, Precise Analysis and Characterization

-

Formulation

Stability enhancement and Lyo development

Concurrent development of mAb and ADC

- Cell Line Development

- mAb Process Development

- ADC Process Development

- Conjugation parameter development

- Downstream process development

- ADC Formulation development

- Analytical method development

- Non GMP mAb Tox, Non GMP ADC DS

- GMP mAb DS, GMP ADC DS

- 12 months

Flexible ADC Manufacturing Processes

Samsung Biologics’ cutting-edge ADC facility is engineered to handle every phase of ADC manufacturing. Our expert team creates tailored timelines that address all ADC components, ensuring flexibility throughout the process. From mAb thawing to formulation and bulk fill-finish, we customize the development journey for each client.

Payload & mAb Prep

- mAb Thawing

- Payload Prep

- UF/DF1

- Reduction

Conjugation

- Conjugation

- Quenching

- UF/DF2

- Chroma- tography

Formulated Bulk

- UF/DF3

- Formulation & Bulk Fill

Integrated ADC Analytical Testing

At Samsung Biologics, all essential analytical tests for ADC development are conducted at a single site, working closely with both the ADC development and manufacturing teams. This integrated approach simplifies the process and guarantees stringent quality control at every stage.

-

Raw Material

- ID for payload/linker

-

IPC Testing

- Protein concentration

-

Chemistry

- DAR

- Residual solvent

- Free drug

-

Biochemistry

- Bioassay

- Antigen binding assay

- Cytotoxidity assay

through the Samsung Life Science Fund.

development technology

technology for ADC

Related Content