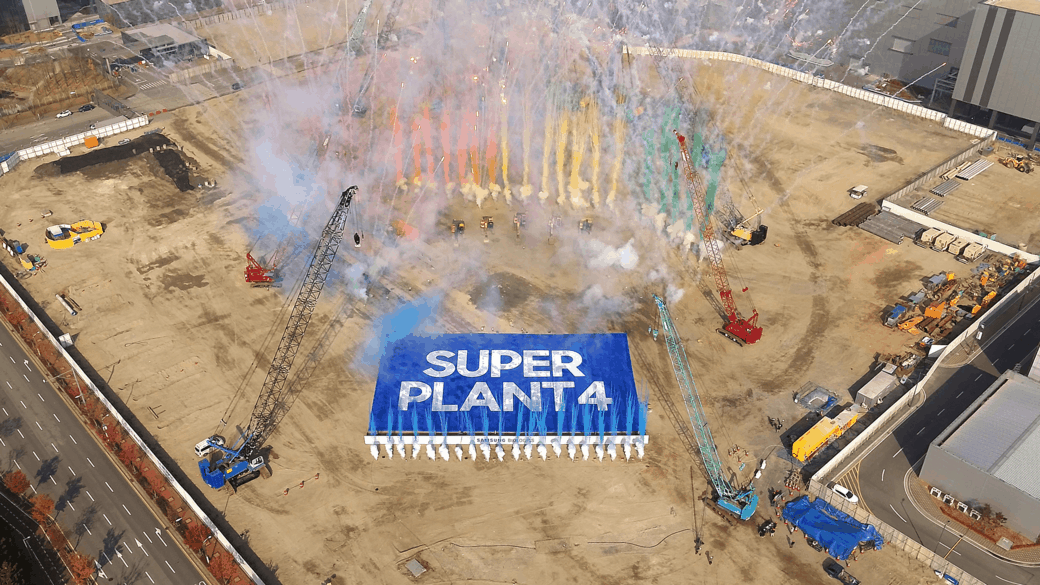

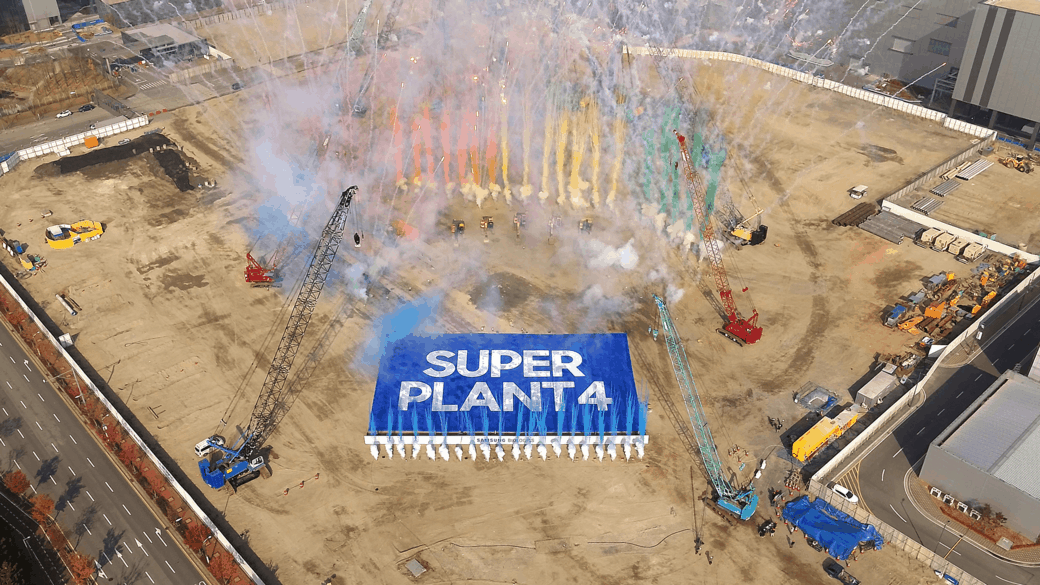

Samsung Biologics breaks ground on Super Plant, the world’s largest and most innovative bio-manufacturing facility

INCHEON, S. KOREA, 18 November 2020 – Samsung Biologics (KRX: 207940.KS) officially began construction of its Plant 4 in Incheon, South Korea. Dubbed the “Super Plant,” the new, multi-story 238,000-square-meter construction will be the world’s largest biopharmaceutical manufacturing facility of its kind boasting 256,000 liters total manufacturing capacity.

In a joint event with the Korean government and the Incheon City, Samsung Biologics showcased a virtual groundbreaking ceremony in light of COVID-19 protocols and announced an investment plan to build the “Future of Biopharma.”

Upon completion of Plant 4, Samsung Biologics is expected to be accountable for a third of the total global bio-CMO manufacturing capacity, offering a combined sum of 620,000 liters from a single site. Plant 4 also features a modular design that will allow flexibility for certain parts of the plant to begin manufacturing activities by the end of 2022, with the goal to commence full operations in 2023.

To ensure client confidentiality and security, equipment and instruments will be fully implemented with data integrity and cybersecurity to reduce risk and offer greater client satisfaction by allowing real-time, secure access to information.

Designed to scale to the varying needs of clients from large-scale commercial manufacturing to sCMO, Plant 4 will be the most flexible one to date with a diverse line-up of bioreactors ranging from 2,000-liters, 10,000-liters, and 15,000-liters. The Super Plant will also provide a full range of CDO, CMO, CRO processes to offer a complete one-stop service including early-stage development capabilities and large-scale commercial manufacturing with a full QC Lab.

“We are committed to bringing client satisfaction to the next level. Plant 4 will add unbeatable value to our capabilities to develop and manufacture bio-medicines with the highest quality and innovative technology,” said Dr. Kim, “We will continue to invest, create jobs, and serve our valued clients as CMO, CDO, and CRO Champion in making life-saving drugs more accessible for all.”

Samsung Biologics plans to also unveil a dedicated Plant 4 virtual showroom online early next month to provide more detailed information and ongoing construction updates of its new plant as part of the company’s enhanced digital transformation efforts. Learn more at www.samsungbiologics.com/plant4

INCHEON, S. KOREA, 18 November 2020 – Samsung Biologics (KRX: 207940.KS) officially began construction of its Plant 4 in Incheon, South Korea. Dubbed the “Super Plant,” the new, multi-story 238,000-square-meter construction will be the world’s largest biopharmaceutical manufacturing facility of its kind boasting 256,000 liters total manufacturing capacity.

In a joint event with the Korean government and the Incheon City, Samsung Biologics showcased a virtual groundbreaking ceremony in light of COVID-19 protocols and announced an investment plan to build the “Future of Biopharma.”

Upon completion of Plant 4, Samsung Biologics is expected to be accountable for a third of the total global bio-CMO manufacturing capacity, offering a combined sum of 620,000 liters from a single site. Plant 4 also features a modular design that will allow flexibility for certain parts of the plant to begin manufacturing activities by the end of 2022, with the goal to commence full operations in 2023.

To ensure client confidentiality and security, equipment and instruments will be fully implemented with data integrity and cybersecurity to reduce risk and offer greater client satisfaction by allowing real-time, secure access to information.

Designed to scale to the varying needs of clients from large-scale commercial manufacturing to sCMO, Plant 4 will be the most flexible one to date with a diverse line-up of bioreactors ranging from 2,000-liters, 10,000-liters, and 15,000-liters. The Super Plant will also provide a full range of CDO, CMO, CRO processes to offer a complete one-stop service including early-stage development capabilities and large-scale commercial manufacturing with a full QC Lab.

“We are committed to bringing client satisfaction to the next level. Plant 4 will add unbeatable value to our capabilities to develop and manufacture bio-medicines with the highest quality and innovative technology,” said Dr. Kim, “We will continue to invest, create jobs, and serve our valued clients as CMO, CDO, and CRO Champion in making life-saving drugs more accessible for all.”

Samsung Biologics plans to also unveil a dedicated Plant 4 virtual showroom online early next month to provide more detailed information and ongoing construction updates of its new plant as part of the company’s enhanced digital transformation efforts. Learn more at www.samsungbiologics.com/plant4

Share article

Related Content