Samsung Biologics CIO Shares Vision for Modernizing Manufacturing Quality

Samsung Biologics is a world-class contract development and manufacturing organization (CDMO) located in Songdo, South Korea.

Founded in 2011, Samsung Biologics has the largest total plant cell culture capacity in the world from a single location: 364,000 L.

The company employs more than 2500 employees including 100+ global expats from 12 countries.

To discuss the company’s vision for modernizing manufacturing quality, I sat down with James Choi, VP and CIO, Samsung Biologics, at the 2019 Veeva R&D Summit.

To date, the company has had a 100% drug substance batch success rate.

It has also undergone more than 20 regulatory inspections and 29 approvals in 4 years.

Managing Content on Samsung’s Shop Floor

Custom applications and paper binders make it difficult to find, update, and track work instructions and procedures, as well as to verify that the right versions are being used.

When Samsung Biologics was looking for a way to deliver the right content to the right station for a connected shop floor, it partnered with Veeva to develop Vault Station Manager, an easy-to-use mobile application in the Veeva Vault Quality Suite.

Vault Station Manager provides manufacturing operators up-to-date content directly on the manufacturing floor.

It delivers documents and videos, including critical work instructions and procedures, from Veeva Vault QualityDocs to tablets located at shop floor stations.

Vault Station Manager allows Samsung Biologics to connect to the shop floor making manufacturing operations more agile and adaptable to changing business requirements with greater velocity.

“It’s challenging,” revealed Choi “to manage and maintain information on the manufacturing floor and ensure operators are working from the latest procedures.

Delivering content directly to manufacturing stations through a mobile application makes it faster for teams to stay up-to-date.”

With Vault Station Manager, manufacturers can increase efficiency and reduce compliance risk by keeping content current and providing operators the information they need to perform their jobs.

Vault Station Manager automatically synchronizes content on station tablets and makes it available for operators, including for offline viewing.

Administrators can centrally manage, distribute and track the content being used at each facility, station, or device gaining complete visibility into the documents and videos manufacturing teams are leveraging.

According to Mike Jovanis, VP Vault Quality at Veeva Systems, “Veeva is modernizing manufacturing operations in life sciences with an advanced mobile application to connect the shop floor.

Veeva Vault Station Manager is making it easier for operators to do their jobs and enable continuous operations across the manufacturing organization.”

What’s Next for Samsung?

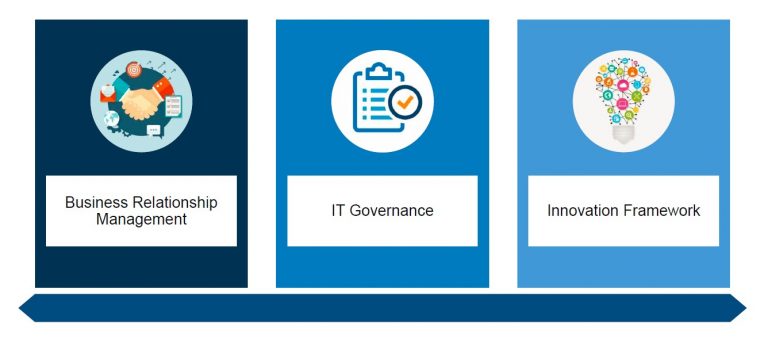

Samsung Biologics is built on Samsung’s innovation DNA as well as its core skills in engineering and operational excellence.

However, noted Choi, “We don’t implement technology for the sake of technology, we implement innovation that drives business value based on a unified IT vision approach.”

The company’s IT directional focus is guided by three value drivers:

Provide quality and efficiency of development and manufacturing services

Deliver blockbuster scalability and operational resilience

Build partnership value and trust

To drive business value based on its unified IT vision, Samsung Biologics is evaluating the use of technologies such as Internet of Things (IoT), Block chain, Cloud BI and Paperless validation.

All rights are reserved by the media that published this article.

Samsung Biologics is a world-class contract development and manufacturing organization (CDMO) located in Songdo, South Korea.

Founded in 2011, Samsung Biologics has the largest total plant cell culture capacity in the world from a single location: 364,000 L.

The company employs more than 2500 employees including 100+ global expats from 12 countries.

To discuss the company’s vision for modernizing manufacturing quality, I sat down with James Choi, VP and CIO, Samsung Biologics, at the 2019 Veeva R&D Summit.

To date, the company has had a 100% drug substance batch success rate.

It has also undergone more than 20 regulatory inspections and 29 approvals in 4 years.

Managing Content on Samsung’s Shop Floor

Custom applications and paper binders make it difficult to find, update, and track work instructions and procedures, as well as to verify that the right versions are being used.

When Samsung Biologics was looking for a way to deliver the right content to the right station for a connected shop floor, it partnered with Veeva to develop Vault Station Manager, an easy-to-use mobile application in the Veeva Vault Quality Suite.

Vault Station Manager provides manufacturing operators up-to-date content directly on the manufacturing floor.

It delivers documents and videos, including critical work instructions and procedures, from Veeva Vault QualityDocs to tablets located at shop floor stations.

Vault Station Manager allows Samsung Biologics to connect to the shop floor making manufacturing operations more agile and adaptable to changing business requirements with greater velocity.

“It’s challenging,” revealed Choi “to manage and maintain information on the manufacturing floor and ensure operators are working from the latest procedures.

Delivering content directly to manufacturing stations through a mobile application makes it faster for teams to stay up-to-date.”

With Vault Station Manager, manufacturers can increase efficiency and reduce compliance risk by keeping content current and providing operators the information they need to perform their jobs.

Vault Station Manager automatically synchronizes content on station tablets and makes it available for operators, including for offline viewing.

Administrators can centrally manage, distribute and track the content being used at each facility, station, or device gaining complete visibility into the documents and videos manufacturing teams are leveraging.

According to Mike Jovanis, VP Vault Quality at Veeva Systems, “Veeva is modernizing manufacturing operations in life sciences with an advanced mobile application to connect the shop floor.

Veeva Vault Station Manager is making it easier for operators to do their jobs and enable continuous operations across the manufacturing organization.”

What’s Next for Samsung?

Samsung Biologics is built on Samsung’s innovation DNA as well as its core skills in engineering and operational excellence.

However, noted Choi, “We don’t implement technology for the sake of technology, we implement innovation that drives business value based on a unified IT vision approach.”

The company’s IT directional focus is guided by three value drivers:

Provide quality and efficiency of development and manufacturing services

Deliver blockbuster scalability and operational resilience

Build partnership value and trust

To drive business value based on its unified IT vision, Samsung Biologics is evaluating the use of technologies such as Internet of Things (IoT), Block chain, Cloud BI and Paperless validation.

All rights are reserved by the media that published this article.

- CDO

- CGMP

- ADC

- Bio Campus

- IR

- CMO

Share article